With shoppers being advised only to leave the home for essential journeys due to Covid-19 and a vast amount of shopping now being done online, product preservation is vital.

Having the right packaging has become essential, especially as many food businesses move to making deliveries as their main source of income.

Food businesses, in particular, need packaging that protects the product from damage and helps to keep it fresh to lengthen its lifespan.

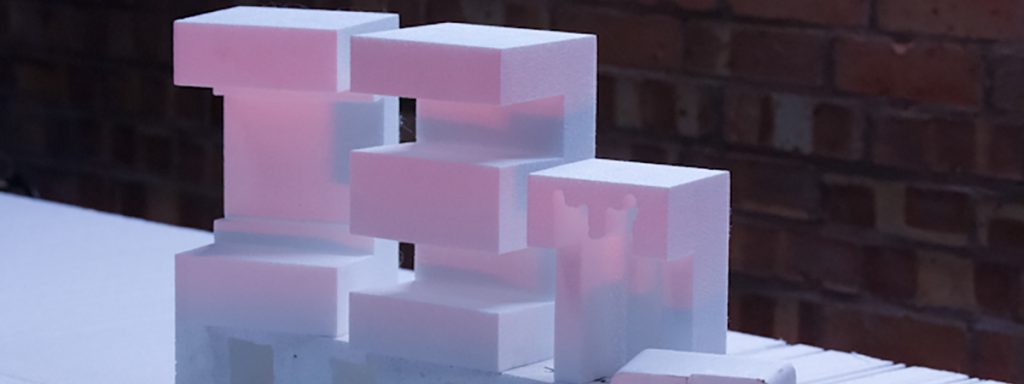

Keep food deliveries fresh with polystyrene packaging

Protecting profits and retaining customers through quality is important at all times, but never more so than in these unprecedented times when economic uncertainty looms.

Using quality, cost-effective polystyrene packaging is a good way to ensure that standards remain high and customers are satisfied.

The long-held popularity of polystyrene packaging is down to its ability to offer exceptional protection and provide insulation.

Choosing polystyrene packaging for food, particularly for deliveries, will help to ensure that it reaches its destination without being damaged or its freshness being unduly affected.

The benefits of using polystyrene packaging for food include:

- Lightweight and easy to transport

- Offers a high level of insulation to help preserve freshness

- Foam-style packaging helps to absorb knocks to protect from damage during transit

- Cost effective

How will polystyrene packaging help to keep food fresh?

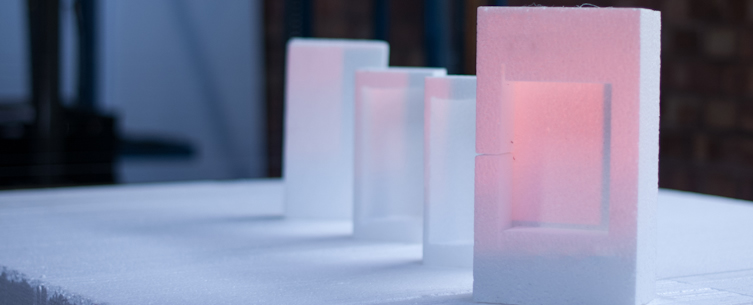

As a poor conductor of heat, polystyrene packaging is ideal for keeping food produce cool and, therefore, fresher for longer.

Due to the way in which it is made – and with 95% of its make-up being air – polystyrene packaging helps to trap air in small pockets. This then protects the atmosphere around the food as an extremely efficient insulator.

This can be applied to hot food and cold food as the air in the packaging will retain its temperature for longer due to it being trapped there.

Protect deliveries

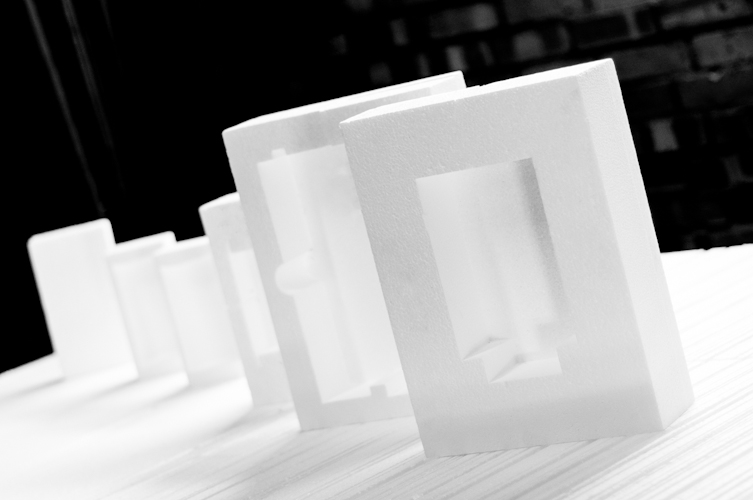

As well as helping to maintain the temperature of food, polystyrene packaging will help to protect fresh food from damage.

This includes helping to prevent bottles being smashed during transportation or boxes dented and the contents broken.

Especially, in regards to maintaining the lifespan and freshness of fresh fruit and vegetables, the buoyant structure of polystyrene packaging will cushion any blows that might bruise or damage the fresh produce.

Bruised fruit and vegetables will see their freshness deteriorate quickly and can even be left unsaleable or inedible due to damage suffered if not packed and treated carefully in transit.

The air that is used in polystyrene food packaging creates a protective atmosphere for delivery and will go a long way in helping to guard against such accidental damage and protect your food stocks.

When your trade has become heavily reliant on delivery it is important to make sure your packing will protect your produce – and your reputation for quality.

Vertapak provides a wide range of top-quality polystyrene packaging that is designed to protect and insulate goods.

To find out more about our polystyrene packaging products and how they could help your business please get in touch.