Polystyrene balls are made by heating and processing hydrocarbon molecules, after which they can either be joined together to make bigger beads or formed into even larger structures. A highly versatile product, most people associate it with stuffed toys or beanbag filler (for which it’s excellent) but there are many other uses too.

Benefits of polystyrene balls

While versatility is one reason why polystyrene has become widely used for a number of applications, there are other benefits. Polystyrene balls are:

- Lightweight

- Durable

- Shock absorbing

- Insulating

- Moisture resistant

Indeed, when looking at the advantages listed above, it’s clear to see why polystyrene has become the material of choice for packaging. As a lightweight product that is also strong and does not absorb moisture, it’s great for ensuring goods arrive safely and intact – but without the costs associated with bulkier, heavier packing materials.

Small foam chips can be used to create a cushioning effect when shipping – so are an ideal choice for electronics and delicate items including medicines, ceramics, glassware and foodstuffs.

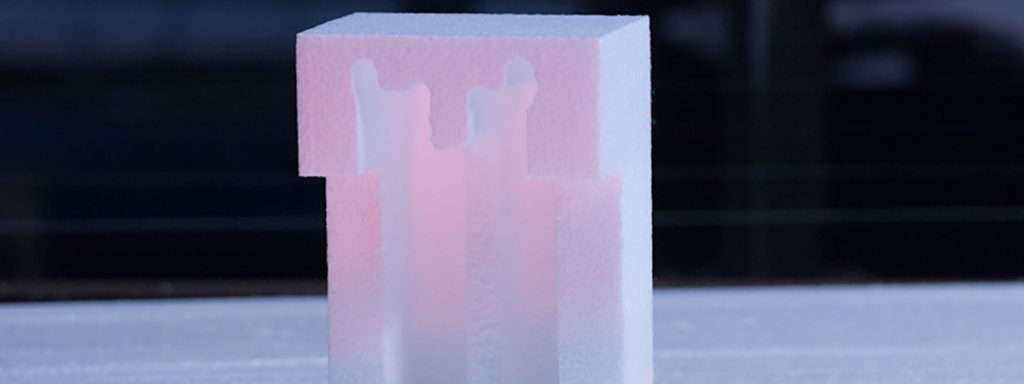

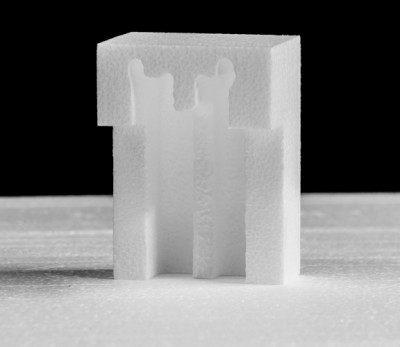

Meanwhile, polystyrene balls can be bound together, moulded or extruded to make other packaging materials such as protective casing which can keep the contents of a package ‘in suspension’ while in transit.

Other uses of polystyrene balls

Takeaway cups, plates and food containers are other popular uses for polystyrene. Rather than being seen as a throwaway item, however, it is important to remember that polystyrene can be recycled.

Made up of 98% air and with no damaging CFC gases, larger polystyrene sheets or moulded products can be broken down into beads and mixed with new beads to form new blocks.

Alternatively, granulated polystyrene can be sent on to be used in other products including plant pots and garden furniture.

In addition, polystyrene balls can be used as insulation in cavity walls. A small hole is cut into a wall or plasterboard, before the beads are inserted with an air blower, filling up the empty space.

This forms a barrier, and due to its insulating properties, locks in heat and improves energy efficiency. (Again, this is one of the reasons why it has established itself as a good material for transporting goods which need to stay at a stable temperature.)

We are proud to design and manufacture polystyrene for a variety of applications including bespoke packaging. If you would like to make an enquiry about our polystyrene products, contact Vertapak using the online form or call the team on 01384 457730.